Time to sh*t or get off the pot if I am going to get this done before December.

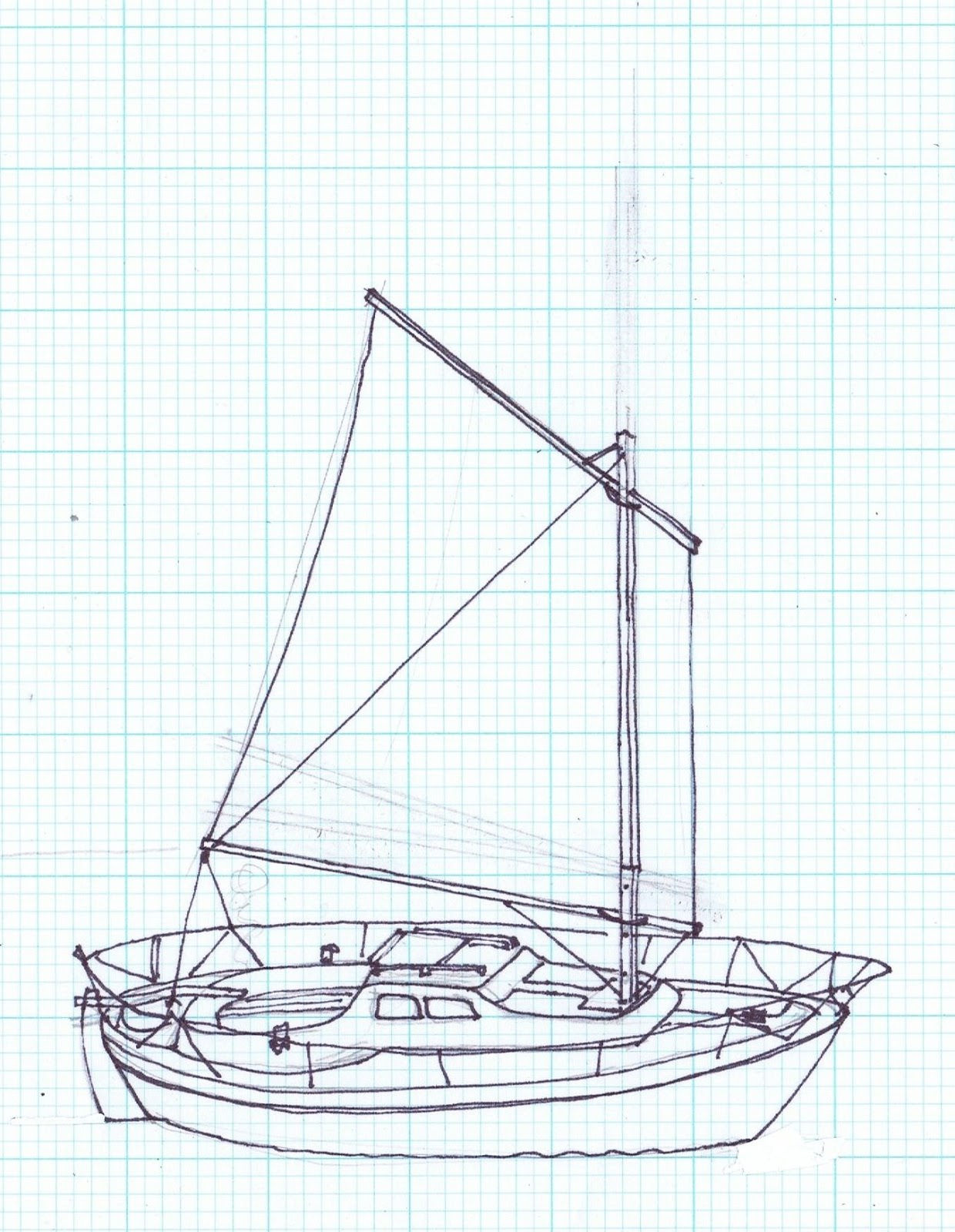

Refer to option 2 on "Lateen/Dhow Sail Rig 2020-2021" page

Sketches to relocate tabernacle and order parts;

2021-10-8 I just do not like the look of this adaptation so back to my steel fabricator for a welded dutch tabernacle

Longer head stay and shrouds

Junk/lug/dhow sail more dhow than lug, maybe loose footed

Forward hatch clear hatch with screen

2021-05-01

So 2020 was a lost year, now what is the plan for 2021-2022?

Redesign mast tabernacle, fore peak hatch for light and ventilation, taller mast at 18ft.

Reefing to be relocated to mast base.

The halyard is easier to use at the mast rather than at the cockpit, so reef lines will also be run to mast base and add a yard down haul line.

|

| 2019-7-2 bimini installed, good sail twist |

2019-6-28 Single line reefing installed with control ends at port side of companionway, halyard at starboard side.

It works but I prefer halyard and reefing at the mast.

2019-5-29

Mast up

October 2018

No more posts on this subject until spring 2019

_________________________________________________________________________________

April 2016

March 2016

Additional grommets punched in sail head (yard edge)

New boom and yard fabricated;

1 1/2" PVC schedule 40 pipe with 1" x 1 1/2" cedar insert set in epoxy.

PVC Schedule 40 properties

Flexural Modulus, psi @ 73°F 360,000 ASTM D790

Western Red Cedar #2 @ 19% moisture content

Modulus of elasticity psi 800,000

Coal Tar Epoxy

Tensile Strength ASTM D638 3,600 psi

Elongation at break ASTM D638 28%

Flexural Strength ASTM D790 4,000 psi

July 2012

May 2015

April 2015

Friday April 17: Mast pivot drilled to 5/8" for copper pipe bushing (1/2" bolt fits in 5/8" OD pipe)

Surface prepared for bowsprit.

March 2015

December 2014

November 2014

Removed winch from former mast and will mount on cabin top near companionway for yard halyard. I will also need longer halyard, I currently haul and secure at base of mast.

August 2014

Single line lazy jack moved to mid-boom

Topping lift to be added to boom end to block at mast base then to cockpit cleat.

50mm triple block for yard halyard added to mast top (was 40mm double block)

50mm double block for yard halyard added to yard (was 40mm single block)

Mainsheet moved to former backstay pushpit ring, double-double block.

Boom cockpit clearance adjusted for bimini and bimini installed

PVC wear pad on steel tabernacle to minimize wear on boom, to be secured better.

Tack vang tensioned to slope boom about 5 deg;

Initial design was junk rig with unstayed or stayed mast, but evolved through full battened Balanced Lug to Balanced Lug without battens then with full battens. The lug/junk sail is just a frugal wing sail, old is new again.

September 2013

No more contemplating and procrastinating under the excuse of planing, it this now a must do before the spring.

The boat will be in Margate NJ for at least 2 months in summer 2014. As is the Bermuda rig at approximately 28'0" will fit under the Ocean City NJ bridge 35'0" clearance, but not the Longport NJ bridge at approximately 25'0" (20'0" during repair work due to be completed before the end of 2013).

Longport inlet which also serves Ocean City has an entrance channel depth at low tide of 16'0" but to get to Margate with Bermuda rig I must go under the Ocean City bridge to a narrow channel through the salt marsh almost to the mainland then down another narrow channel through salt marsh to Margate, about 8 nm.

With the balance lug as designed I will have 20'0" with 1st reef or 23'0" without reef, enough for the Longport bridge which will make Margate only 2 nm from the inlet.

The mast dutch tabernacle will also open up more options on the NJ Intercoastal Waterway and DelMarVa back-bays.

So haul-out this winter will include the rig change and interior upgrades for more comfort.

A Junk sail may be a future iteration?

Mast

Checked with my lumber supplier for quote and delivery. The mast 16ft above deck will be western red ceder for better dimensional stability, with boiled linseed oil finish.

February 2014 mast ordered.

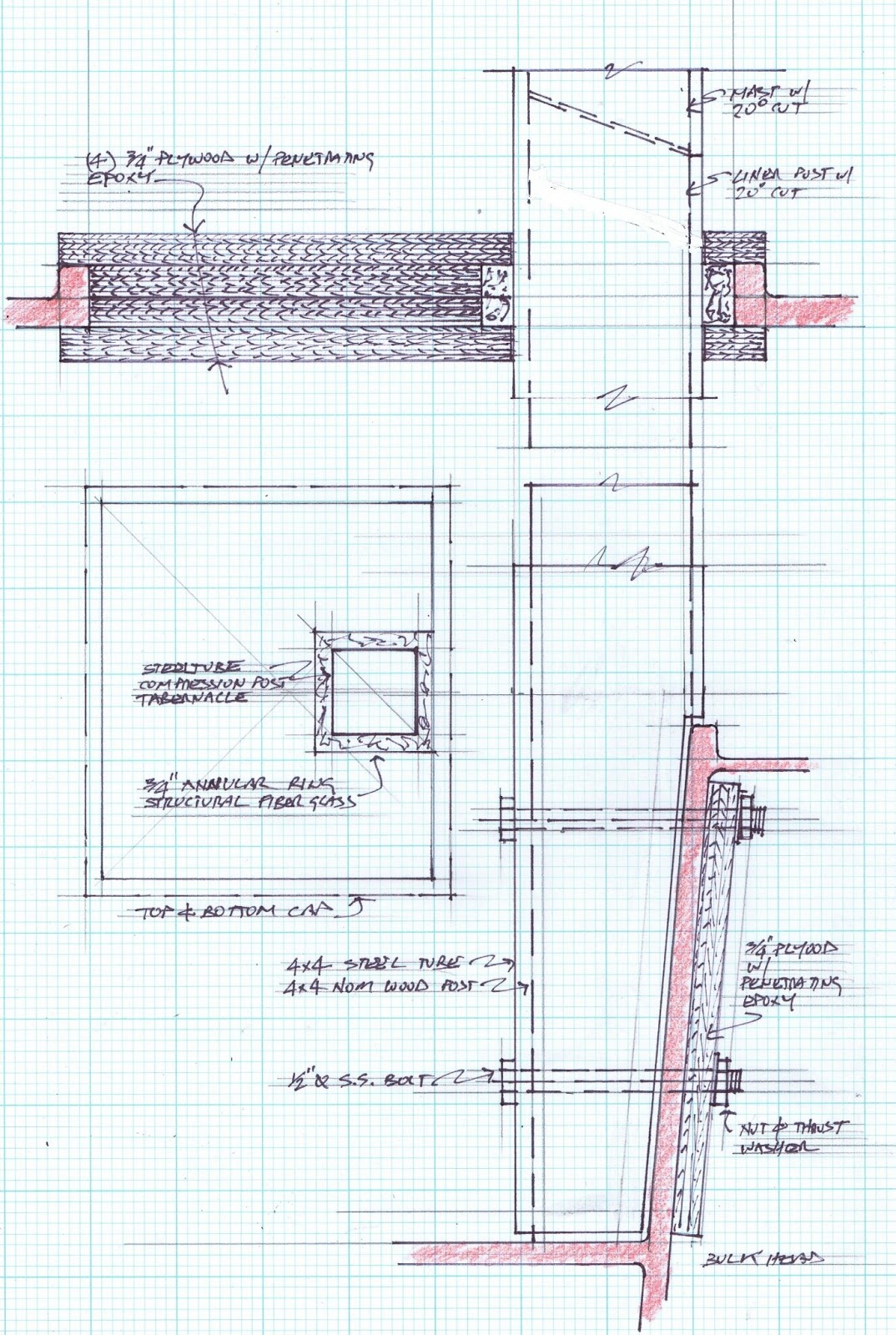

Tabernacle/Compression Post

The mast will sit in an 8ft, 4x4x3/8 steel tube tabernacle/compression post, secured at fore peak step bulkhead and hatch solid infill.

June 2013

Back to work on this June 2013, two weeks of thunderstorms has cut into sailing time.

Tabernacle post was 3/8" steel square tube salvaged from a building I was working on, the contractor did the initial cutting and drilling holes. This week to lighten the tube I removed steel below the forward pivot and ground edges. More grinding and descaling then a bare metal primer.

The mast will swing within the 4x4 steel tube on a 1/2" galvanized steel bolt, and be secured laterally by tube side walls and fore/aft with high and low 1/2" galvanized steel bolts.

July 3, 2013

Grinding, cutting, sanding and wire brush rust and scale complete. Coal Tar Epoxy surface priming on the first almost dry day for three weeks.

The tabernacle/compression post provides for ease of lowering the mast.

Other options that were explored; deck stepped tabernacle with stays. full bury fixed mast with and without stays.

Sail

A number of sail options were explored; fabrics, DIY, sail maker and non-traditional sources.

-Dacron with battens, a superior product would be a budget killer, not completely ruled out.

-DIY Tarp, the lowest cost option, maybe good for testing sail shape and patterns but a short in service life.

-Custom tarp, lower cost and probably superior craftsmanship than DIY but short service life.

-UV treated cotton/canvas "tarp" sail without battens, custom or DIY lower cost than Dacron, long service life, but heavier.

-UV treated synthetic "marine awning" material custom made with reinforced edges and reinforced grommets, higher cost than tarp options, but less than half the cost of Dacron, with a service life equal to or greater than Dacron. The main disadvantage over Dacron will be a potential for stretch and shape deformation.

February 2014 sail ordered.

KISS sail 11 lbs (5 kg) original sail approx 10 lbs

Unstayed mast 46 lbs (21 kg) original 24ft aluminum mast approx 75 lbs

Yard 10 lbs (5 kg)

Boom 15 lbs (7 kg) original 10ft aluminum boom approx 25 lbs

Steel tabernacle 113 lbs (51 kg)

Total prelim 195 lbs (89 kg) Total original approx 110 lbs (50kg)

(assuming standing and running rigging no weight change)

Additional weight 85 lbs but lower including 56 lbs below deck

Next;

Reefing

Options explored;

|

| 2019-6-17 battens installed |

|

| 2019-6-14 sail installed |

2019-5-29

Mast up

October 2018

|

| Balanced lug with headsail on sprit |

|

| Junk/Lug sail 2018-10-3 |

|

| Ulla Junk-Lug Spars Existing mast and forestay. 2018-10-3 |

|

| Boom and one batten cut from 16 ft cedar deck board. The two halves of the boom will be opposing grain glued to create 1 1/2" x 2" section. 2018-10-7 |

|

| Drywall screw preset before glue spread |

|

| Glue evenly spread |

|

| Drywall screw temporary clamp. Screws to be replaced with wood dowel after cure |

|

| Rain protected during cure 2018-10-8 |

|

| Plane high spots |

|

| Sand and ease edges |

|

| 2 part epoxy penetrating sealer |

|

| Topside paint |

|

| Cedar battens coated with 2 part penetrating epoxy. To be cut to length when matched with sail. |

|

| Former standing lug yard, parrel removed, holes pluged, tabs removed. Battens one coat topside paint. |

|

| Left to right Boom, yard, battens |

|

| Boom and yard sail, parrel, and halyard tabs installed (through bolted truck bed tie downs) |

|

| Junk/Lug sail, battens to be trimmed. |

April 2016

March 2016

|

| Mast raised |

|

| Outboard installed |

Additional grommets punched in sail head (yard edge)

New boom and yard fabricated;

1 1/2" PVC schedule 40 pipe with 1" x 1 1/2" cedar insert set in epoxy.

|

| 1 1/2" cedar insert ripped from cedar deck board , edges eased. |

|

| Clear PVC cleaner/primer and glue, end caps and union. |

|

| Pipe sections glued, extra length at one end for epoxy pour. |

|

| Cedar insert to end of pipe at other end. |

|

| End cap glued in place. |

Flexural Modulus, psi @ 73°F 360,000 ASTM D790

Western Red Cedar #2 @ 19% moisture content

Modulus of elasticity psi 800,000

Coal Tar Epoxy

Tensile Strength ASTM D638 3,600 psi

Elongation at break ASTM D638 28%

Flexural Strength ASTM D790 4,000 psi

July 2012

|

| Next sail, also full batten balanced lug |

May 2015

|

| Ulla Gaff Rig with headsail on Bowsprit. I will conclude my balanced lug experiment this year and begin work on a gaff sail in 2016 |

April 2015

|

| Bowsprit April 18 |

Friday April 17: Mast pivot drilled to 5/8" for copper pipe bushing (1/2" bolt fits in 5/8" OD pipe)

Surface prepared for bowsprit.

|

| Bobstay eye |

|

| Bow Sprit |

March 2015

.jpg) |

| Preliminary batten layout. |

December 2014

|

| Next |

November 2014

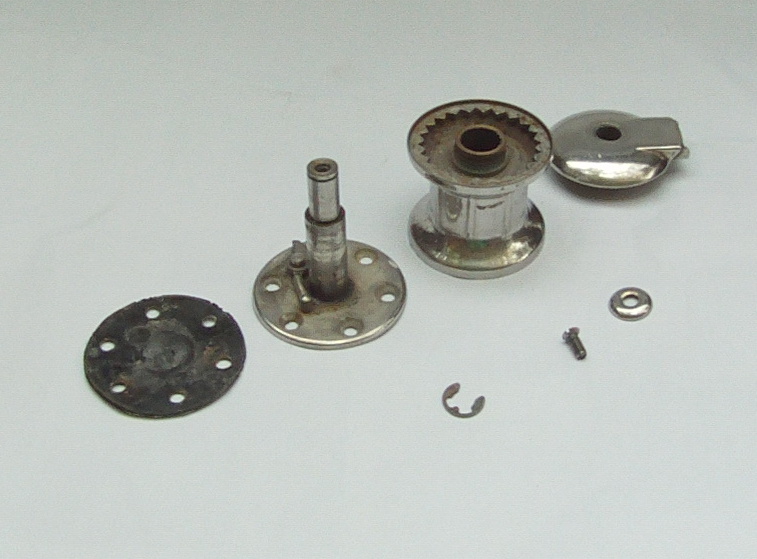

Removed winch from former mast and will mount on cabin top near companionway for yard halyard. I will also need longer halyard, I currently haul and secure at base of mast.

|

| Halyard Winch cleaned, simple double ratchet operation. |

|

| Halyard winch assembled |

August 2014

Come back later for a cleaned up page.

Parrels added to battens.Single line lazy jack moved to mid-boom

Topping lift to be added to boom end to block at mast base then to cockpit cleat.

50mm triple block for yard halyard added to mast top (was 40mm double block)

50mm double block for yard halyard added to yard (was 40mm single block)

Mainsheet moved to former backstay pushpit ring, double-double block.

Boom cockpit clearance adjusted for bimini and bimini installed

PVC wear pad on steel tabernacle to minimize wear on boom, to be secured better.

Tack vang tensioned to slope boom about 5 deg;

Initial design was junk rig with unstayed or stayed mast, but evolved through full battened Balanced Lug to Balanced Lug without battens then with full battens. The lug/junk sail is just a frugal wing sail, old is new again.

|

| Full batten balanced lug sail installed. Need to add topping lift and lazy jacks. |

|

| Yard and boom lateral stiffener added, battens added. Using GoPro so some fish eye lense distortion. |

|

| Battens ripped from cedar deck boards,one coat spar varnish |

|

| Next iteration will be bowsprit with jib on Alado roller furler and full batten balanced lug. |

|

| Full sail |

|

| First reef |

|

| Storm/riding sail |

|

| Second reef |

|

| Balanced lug rig. Still some adjusting to lazy jacks and reefing, but ready for summer. |

|

| Steel tabernacle/compression post |

September 2013

No more contemplating and procrastinating under the excuse of planing, it this now a must do before the spring.

The boat will be in Margate NJ for at least 2 months in summer 2014. As is the Bermuda rig at approximately 28'0" will fit under the Ocean City NJ bridge 35'0" clearance, but not the Longport NJ bridge at approximately 25'0" (20'0" during repair work due to be completed before the end of 2013).

Longport inlet which also serves Ocean City has an entrance channel depth at low tide of 16'0" but to get to Margate with Bermuda rig I must go under the Ocean City bridge to a narrow channel through the salt marsh almost to the mainland then down another narrow channel through salt marsh to Margate, about 8 nm.

With the balance lug as designed I will have 20'0" with 1st reef or 23'0" without reef, enough for the Longport bridge which will make Margate only 2 nm from the inlet.

The mast dutch tabernacle will also open up more options on the NJ Intercoastal Waterway and DelMarVa back-bays.

So haul-out this winter will include the rig change and interior upgrades for more comfort.

A Junk sail may be a future iteration?

|

| Dutch Tabernacle compression post December2013 |

|

| Mast tabernacle hatch infill rough with steel scrap from tabernacle. March 2014 |

|

| Hatch infill/mast partner rough fit. March 2014 |

Mast

Checked with my lumber supplier for quote and delivery. The mast 16ft above deck will be western red ceder for better dimensional stability, with boiled linseed oil finish.

February 2014 mast ordered.

Tabernacle/Compression Post

The mast will sit in an 8ft, 4x4x3/8 steel tube tabernacle/compression post, secured at fore peak step bulkhead and hatch solid infill.

June 2013

Back to work on this June 2013, two weeks of thunderstorms has cut into sailing time.

Tabernacle post was 3/8" steel square tube salvaged from a building I was working on, the contractor did the initial cutting and drilling holes. This week to lighten the tube I removed steel below the forward pivot and ground edges. More grinding and descaling then a bare metal primer.

The mast will swing within the 4x4 steel tube on a 1/2" galvanized steel bolt, and be secured laterally by tube side walls and fore/aft with high and low 1/2" galvanized steel bolts.

July 3, 2013

Grinding, cutting, sanding and wire brush rust and scale complete. Coal Tar Epoxy surface priming on the first almost dry day for three weeks.

|

| Compression Post/Tabernacle 4x4x3/8 steel tube weight 8 x 18.84 lbs x 0.75 = 113.04 lbs (1/4 of material removed in fabrication) |

The tabernacle/compression post provides for ease of lowering the mast.

Other options that were explored; deck stepped tabernacle with stays. full bury fixed mast with and without stays.

Sail

A number of sail options were explored; fabrics, DIY, sail maker and non-traditional sources.

-Dacron with battens, a superior product would be a budget killer, not completely ruled out.

-DIY Tarp, the lowest cost option, maybe good for testing sail shape and patterns but a short in service life.

-Custom tarp, lower cost and probably superior craftsmanship than DIY but short service life.

-UV treated cotton/canvas "tarp" sail without battens, custom or DIY lower cost than Dacron, long service life, but heavier.

-UV treated synthetic "marine awning" material custom made with reinforced edges and reinforced grommets, higher cost than tarp options, but less than half the cost of Dacron, with a service life equal to or greater than Dacron. The main disadvantage over Dacron will be a potential for stretch and shape deformation.

February 2014 sail ordered.

|

| Simple sail without battens, 170 sf = 19 yds @ 9 oz/yd = 170 oz = 11 lbs. |

KISS sail 11 lbs (5 kg) original sail approx 10 lbs

Unstayed mast 46 lbs (21 kg) original 24ft aluminum mast approx 75 lbs

Yard 10 lbs (5 kg)

Boom 15 lbs (7 kg) original 10ft aluminum boom approx 25 lbs

Steel tabernacle 113 lbs (51 kg)

Total prelim 195 lbs (89 kg) Total original approx 110 lbs (50kg)

(assuming standing and running rigging no weight change)

Additional weight 85 lbs but lower including 56 lbs below deck

|

| Spinnaker for downwind running/reach |

|

| Jib blade on spinnaker halyard for close hauled |

|

| Boom, sheet end |

|

| Spinnaker |

Next;

Reefing

Options explored;

|

| Full Batten Balanced Lug Rig with unstayed tabernacle mast |

|

| Sail plan stayed mast with Dutch tabernacle Full batten lug (Junk) sail 190 sf. |

|

| Original Bermuda Rig

Main 111sqft (10sq meter) + Jib 74.4 sq ft (6.7 sq meter)=185 sq ft (16.7 sq meter)

|

.jpg)

HI, Fun to see someone try a new approach for this giant little sailer.Years ago I sailed and owned the # 666 Havsfidra.

ReplyDeleteIt was undercanvasd unless it really got some wind. I seldom sailed without the large genua hoisted. Often the "cast iron genua" was used.. (VP MD1b).

New (brownish) sails was bought from Lee Sails in Hong Kong. Lee Sails later made me lug sails for a later smaller boat.

Lug sails are not hight techs and can't beat a modern rig in a fight close to wind. But in all other directions the lug rigged will not slip after or even, in som directions be winner. The lower center of gravity is a good feature as is the simplicity IF one let it be a KISS rig. There is not much to gain in over engineering a lug rig. Something one maybe should borrow from the Chinese junk sail is not the battens but the rope between mast and sail. Lowering the sail when the wind is still strong is then greatly simplified. I would, having had the simpler set up, trade any losses due to less favourable aerodynamics,

for greater handiness. As we all know: If you have to beat against the wind your goal is wrong.

The name, when spelled and pronounces "Ulla", is a common girl name in Sweden.

Nice reading about her.

Dejan Petrovic

Sweden

Hi there!

ReplyDeleteInteresting read!

I'm thinking about how to do a junk rig conversion of a Storfidra (big sister of a Havsfidra). I guess I would do it about the same way as you have, although I rather like the idea of having the actual mast going all the way down to the keel, or at least inside the boat. Also, I think I would try to find some kind of lamp post, like Roger Taylor did on his recent conversion (see youtube!).

Best regards,

Mikael, also Sweden

The Storfidra is a larger boat than the Havsfidra, so more sail area probably means taller and stiffer mast. This could be done with a swing tabernacle but a fixed unstayed mast secured at partner and keel would probably be better. As a swing tabernacle with the larger loads from a larger sail area the mast cross section and depth of "bury" in the tabernacle grow larger.

DeleteI arrived at mast height starting with boom length and yard rake, projecting sail area into this limit which gave me a minimum height for mast. The length of mast then determined desirable cross section and material options. Solid cedar was lighter than a similar aluminum hollow cross section, also cheaper and available.

I would suggest drawing a junk sail of the same sail area as your current main and headsail, locate the center of effort of the junk sail slightly forward of the boats center of gravity. Mast location will be a function of available space below but should be forward of the current mast location.

I added mast rake for aesthetic reasons, but mast rake can also be used to move the sail center of effort to the desired location. Sail center of effort location can also be manipulated by location and tension in the mast parrels, and tack downhaul/vang. My sail center of effort can be manipulated within a range of 20 cm (8 inches) to 40 cm (16 inches) forward of the boat center of gravity.

The Havsfidra was originally built with a lifting ring under the sole secured to the keel/ballast for a balanced crane lift, this is the boat center of gravity.

My design is for a balanced lug but as I experiment this summer, junk sail battens may be added. The current issue I have with my new rig is a tendency for the sail forward of the mast to back-wind in gusts, so far I have been adjusting the yard parrel and downhaul/vang with limited success on the reducing back-winding.

I do need to adjust the tension in the lazy jacks/ topping lift for better sail control, but so far it sails well to within 30 degrees of the wind, and is well balanced for sailing in steady winds without touching the tiller.

very, very interesting…

ReplyDelete…did you already speak with sebastian from http://tuchwerkstatt.de/product/junksails.html – he's an expert when it comes to junk rigs…

just sayin'.

So, what's the latest...? I'm trying to modify a 22'6" steel(3mm) Roberts designed Spray...and your vessel is about the same length...Though I wouldn't be burying the Tabernacle so deep into the forward berth area...Just re-enforcing the under deck support area...retaining the forward berths openness...The front of the cabin stands approx 10" above the deck in a vertical and rounded configuration...I was thinking of extending the tabernacle up from it about 3 to 4 ft and braced externally for extra rigidity...

ReplyDeleteI'm interested in how yours performed for you....ease of operation and deck walk around .

Spring is almost here and March work will include installing the headsail alado roller furler, making stronger lighter yard and boom, changing to a wire topping lift, and wire shrouds. The rig performed well on my trip last year down the Chesapeake to the Choptank and this year I will be going to Tangier Sound.

DeleteWith a steel boat you may have more options to reinforce the deck under the tabernacle, but the advantage of a long bury is a reduction in the bending moment at the deck. Not having a long bury will result in an increased bending moment and compression load at the deck. Stiffening the deck may provide enough stiffness for the bending moment but the compression load will require either a post or portal frame to transfer the load to the keel or keelson. All very doable with steel, more complicated with fiberglass.

The bending moment can also be reduced with use of shrouds and stays, I use shrouds due to greater flex in my 4x4 cedar post than a larger section cedar post or an aluminum tube. Shrouds reduce the option for a windvaning of the lug or junk sail.

Still investigating a kort nozzle but it looks like no real advantage for me.

Hello! I love this project. I’m curious what your reefing system is for the battened lug sail?

ReplyDeleteI am still working on reefing; at the battens or half battens. It probably will not be resolved until sometime in the spring of 2019. Initially it will be with individual tie downs then progress to a single line system.

ReplyDelete